SUSTAINABILITY & SMALL BUSINESS BLOG

Fabrics, Circularity + Innovation

FABRICS, CIRCULARITY + INNOVATION

Fabrics and how they are made have been a topic of conversation for years, particularly within the fashion industry. Although there have been some fantastic innovative revelations when it comes to fabrics and creating more sustainable options, there are still huge issues with global fabric production. Fabric production processes can be extremely harmful to the people who create them and the planet.

DAMAGING PROCESSES

Fabric Dyeing

For fabric dying alone, the textile industry uses between six to nine trillion litres of water each year. If you need a visual representation, that’s like filling two million Olympic swimming pools every year with fresh water. A pretty colossal amount of water, that is hard to comprehend. Not only is the amount of water used shocking, almost three-quarters of all the water used by dye-mills across the globe ends up as undrinkable waste. Virginia Newton Lewis, a senior policy analyst at Water Aid tells Vogue that “some of the chemicals used in Indian dye houses are actually banned in Europe”. In the dyeing hubs of Bangladesh, India and China, chemicals and waste dyes are often pumped back into rivers which then damage local ecosystems and harm plants and animals. This is one of the major devastating consequences of western countries outsourcing their production: they are also transferring the damage that comes with it.

The fashion industry is responsible for up to one-fifth of industrial water pollution. In Bangladesh – a producer country with a lack of regulation and enforcement – wastewater is commonly dumped into rivers and streams, leaving a concoction of carcinogenic chemicals, dyes, salts and metals polluting drinking water sources. In an article on CNN Style, Ridwanul Haque, chief executive of the Dhaka-based NGO Agroho said that rivers and canals that run through Dhaka have turned a ‘pitch black colour’ due to the sludge and sewage produced by textile dying.

Although not all chemicals and solvents used are hazardous, the World Bank has identified 72 toxic materials that stem solely from fabric dying. Once these chemicals hit waterways, they build up to reduce plants’ ability to photosynthesize which kills aquatic plants and animals. Not only this, but the chemicals and heavy metals released from fabric dyeing processes can build up in the body increasing the risk of cancers, illnesses and skin problems to those that ingest polluted water.

Cotton Production

It doesn’t stop there. The humble t-shirt also comes with a huge price – a whopping 713 gallons of water is needed to make one cotton t-shirt. Not only is the water consumption huge, but the pesticides used in cotton production is also staggering – 4% of all world pesticides and 10% of insecticides are used in cotton growing. Cotton is the world’s largest non-food crop and just six countries produce 80% of all cotton.

Not only is the production of cotton wasteful, but the farmers and producers of cotton are very often left out of ‘sustainable’ and ‘ethical’ talks. The fashion industry generally fails to focus on the entire supply chain and those that grow the cotton are more often than not left without a living income. Cotton has always played a major role in the economic and social development of the economies of traditionally pillaged countries. Many cotton farmers live below the poverty line and depend on the people in the middle of the supply chain who regularly pay below the cost of production. If this is something you’d like to learn more about there’s a great podcast that we’d recommend called ‘Conscious Chatter’ by Kestrel Jenkins – look out for the episodes called ‘The Root’.

Farmers in India are facing measures that will negatively impact their lives, and are currently taking part in the largest protest in the history of the world. Narendra Modi, India’s Premier has called for new laws are anti-farmer and pro-corporation. Protesters are camped out on key routes into New Delhi in response to the new farming laws – across India, farmers are concerned that the three new laws will make them vulnerable to exploitation by big corporations, contribute to a decrease in earnings and put an end to the MSP system. The MSP system means that farmers who sold their crops at auction would at least get a Minimum Support Price, which is the Government’s price to buy farm produce. Stand for Humanity, an Instagram account created by Yazzi, (@standforhumanity) posts information and resources on this topic which we’d recommend checking out and getting clued up on this. India is the largest producer of cotton and 70% of the world’s spices come from India. Capitalist structures erase the work and the stories of the people behind the products we consume (especially when those people are Black and Brown) – this is one of the many reasons why it’s so important as consumers to actively engage, educate ourselves and support protests and movements surrounding workers rights.

Colonialism + Textile Waste

We also need to address colonialism globally and particularly within the fashion industry and the effects this has on garment workers today. Colonial mentalities and practises are how businesses operate today and systems ensure that extraction and exploitation of resources, from materials to labour, are the means for many fast fashion companies’ supposed infinite growth and success. Almost all of the resources that are extracted come from nations that are destabilized from colonial violence. If you’d like to support garment workers, then we’d suggest following, engaging and donating to organisations such as Labour Behind the Label. We’d also recommend donating to The Slow Factory and taking part in their Open Education.

Whilst there are many harmful practises that go hand in hand with textile production, another harmful practise is fabric and clothing waste. The UK alone produces 206,456 tonnes of textile waste a year. In the US, 15 million tonnes of textile waste is produced each year – a number that has doubled over the last 20 years. The number of garments produced annually has doubled since 2000 and exceeded 100 billion for the first time back in 2014. As a global issue, it is estimated that a whopping 92 million tonnes of textile waste is created annually, from the fashion industry alone. If you were in need of any further visualisations of the scale of this issue – every second, the equivalent of one garbage truck of textiles is landfilled or burned globally.

For further reading of this, The OR Foundation has great resources on the second-hand garment industry in Accra, Ghana. Liz Ricketts and Branson Skinner, the founders, have spent many years studying the second-hand trade market in Accra, in particular at the Kantamanto Market. You learn more about the direct issue of over-consumption and support their work financially by heading to their website ‘Dead White Man’s Clothes’.

FABRIC INNOVATIONS

We need to drastically reduce the harm that fabric production causes at every stage and begin using and thinking about different alternatives when it comes to fashion.

Econyl

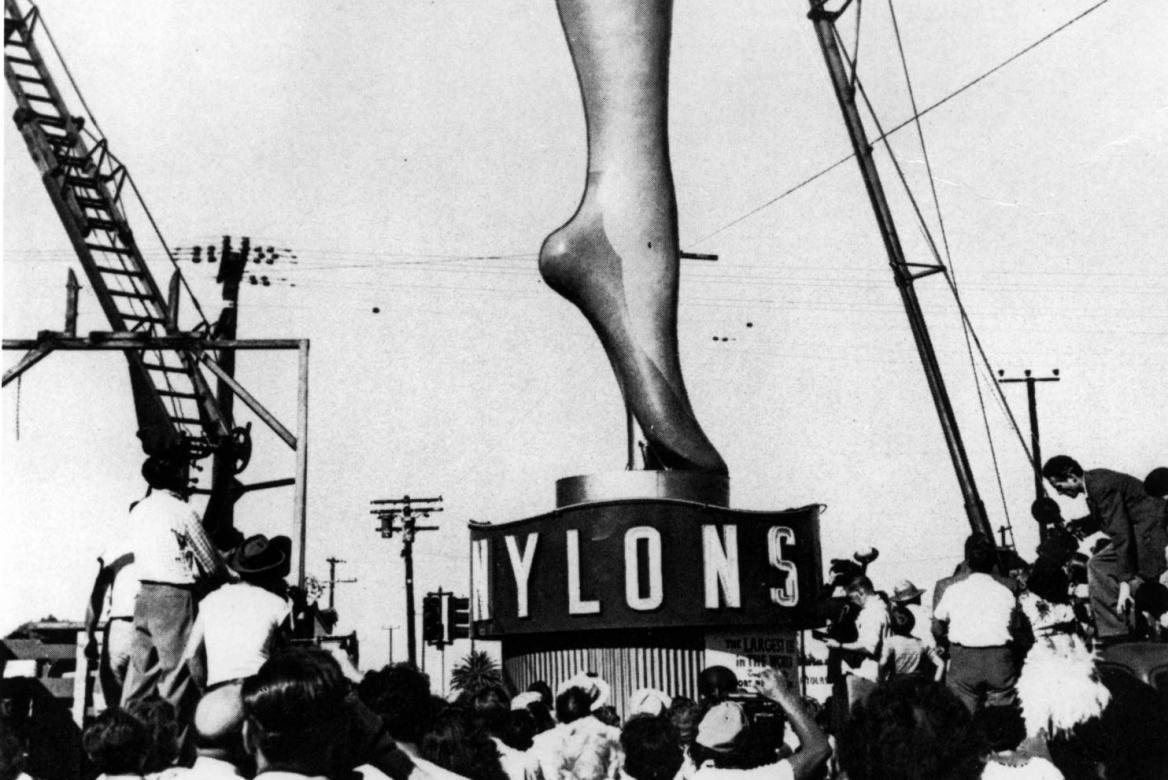

You may have heard of Nylon – but have you heard of Econyl? Econyl is infinitely recyclable – it’s a by-product of Nylon and works and acts exactly the same as brand new Nylon, just more planet-friendly!

Nylon was first introduced to consumers in 1938 and because of its strength and durability, it was used for military products during WW2 and also replaced anything that was once made from silk. Whilst at the time, this fabric seemed like a great alternative – it has now become a huge polluter within the fashion and textile industry.

Manufacturing Nylon is a nasty business – it creates nitrous oxide, which is a greenhouse gas 310 times more potent than carbon dioxide. It is essentially a type of plastic that is derived from crude oil, which is then put through a damaging chemical process, which then results in a strong stretchy fabric – great for practicality but not so much for the planet.

Econyl is a great alternative to Nylon and is a product that can help you close the loop. Waste made from Nylon, is now transformed into Econyl and is exactly the same as brand new Nylon and can be recycled, recreated and remoulded, continually!

Recover

As you now know, cotton has a huge impact on the world, both people and planet. If you’re looking for an alternative then keep your eyes peeled for Recover.

Recover is a great company who makes the lowest-impact cotton fibre in the global market. According to the Higg MSI Index, their recycled cotton fibre is the most sustainable cotton solution available today. As of last year, the company secured funding to allow for scale of its operations and to grow its output over the next five years. This is fantastic news for the company which was founded 70 years ago and will help to increase its output to 200,000 metric tonnes of recycled fibre per year.

When you’re next shopping for clothes, take note of what the garment is made out of. Ensuring you’re considering the contents of your garments and where it has come from will help you to make informed decisions when it comes to making more ethical clothing purchasing decisions.

Pineapple Leather

Something a little different into the mix! Fruity leather. This innovation is an alternative to the harmful practises of leather goods, and for Pinatex, uses the leaves of pineapples grown in the Philippines. These leaves are a by-product from existing pineapple harvest, so any raw material requires no additional environmental resources to produce. Pinatex’s practice is completely animal-free and requires a lot less water and no harmful chemicals that are toxic to wildlife. Any leftover leaf waste is further recycled and used for fertiliser or biomass.

Pinatex was founded and created by Carmen, a leathergoods expert, back in the 1990’s. Carmen was shocked by the environmental impact of mass leather production and chemical tanning and was driven to find a sustainable alternative for our leather goods!

Pinatex is a Co-Operative business which means that it is owned and operated by the people who use its products and services and benefit from what the company has to offer. Co-operative businesses realise the economic, cultural and social needs of the organisation’s members and its surrounding community. They exist to serve and strengthen the community.

CIRCULARITY + DEADSTOCK

Deadstock fabric often means that production has been discontinued leading to a quantity of leftover fabric. For example a fabric mill has made too much and it is no longer saleable, fashion businesses have over-estimated their needs or there are small damages to the fabric making it non-usable for the particular brand it was made for.

Here at The Emperor’s Old Clothes we take pride in sourcing our fabrics from local and non-local deadstock fabric suppliers. Nothing excites us more than receiving a van load of new fabrics for you to enjoy designing your ethical clothes with! By using deadstock fabric, we are using up what is already available – rather than contributing to the harmful processes of creating more fabric and essentially contributing to the waste that it creates. This is what makes your sustainable clothing unique!

Using deadstock fabric can be tricky, as it means we have to measure each individual piece and calculate what we can make from it. Whilst this is great for reducing our waste, it can also mean that once it’s gone, it’s gone.

By building a slow fashion business model that creates garments on a made-to-order basis, you are actively changing the narrative and allowing for less waste. This equates to more responsible clothing production practices as you are only creating what has already been ordered. In comparison to this, fast fashion brands create hundreds of thousands of stock (one fast fashion brand has 14,005 styles of just dresses). More often than not, this stock, when unsold, ends up in landfill and pollutes the planet contributing to the 15 million tonnes of textile waste we mentioned earlier in the blog. Last year for Fashion Revolution, our alumnus Cress wrote a blog all about fabric waste and sustainable fashion – get clued up here.

If you’re looking for ways to make your wardrobe more circular, then how about using old things around your home, or even in your wardrobe and upcycling them to create something new. Giving something a new life, whether you cut up an old jumper and make it into a cushion, or sew a badge over a hole in a jumper – you are actively giving something a new life and reducing your waste!

At Emperor’s we help make your garments circular by offering alterations when things go wrong or you fancy a switch up. Perhaps you have a skater dress and feel that a circle two-piece might fit in better with your wardrobe? Getting in touch with us to see how we can help you with alterations is a step in the right direction in making sure your Emperor’s garments fit you properly and are styled so that you’ll wear them again and again and again.

Written by Ella Anais Gilchrist, Marketing and Graphic Design Assistant, edited by Cecily Blondel, Owner